1

/

of

4

Domestic sewage plant industrial wastewater treatment equipment

Domestic sewage plant industrial wastewater treatment equipment

Product descriptions from the supplier

Overview

Product Description

Domestic Waste Water Treatment System

The domestic sewage treatment equipment adopts the "A2O+BAF+UV Disinfection" process, ensuring that the water quality of the effluent can stably meet the "Discharge Standard of Pollutants for Municipal Wastewater Treatment Plants" (GB18918-2002).

|

|

Product Composition

The domestic sewage treatment equipment mainly consists of the following units: grating adjustment tank unit, A2O unit, BAF unit, and UV disinfection unit.

Grating Adjustment Tank Unit: Includes grating well and adjustment tank.A2O

Unit: Includes anaerobic tank, anoxic tank, aerobic tank, and sedimentation tank.

BAF Unit: Includes BAF pool.

UV Disinfection Unit: Includes UV disinfection equipment.

|

Details Images

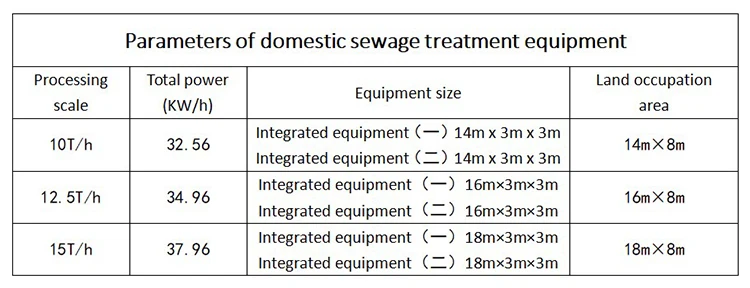

Product Parameters

|

|

|

Technical Principle:

The domestic sewage treatment equipment uses the "A2O+BAF+UV Disinfection" process.

The A2O process is short for Anaerobic-Anoxic-Oxic, which utilizes the biological processes of anaerobic, anoxic, and oxic conditions to perform denitrification and phosphorus removal. Within the A2O process flow, BOD5, SS, and nitrogen and phosphorus in various forms are removed step by step. In the anaerobic and anoxic stages, the microbial community is primarily composed of denitrifying bacteria and polyphosphate accumulating organisms, while in the aerobic stage, it is mainly composed of nitrifying bacteria and polyphosphate accumulating organisms.

BAF, or Biological Aerated Filter, is a biofilm treatment process coexisting with solid, liquid, and gas phases. It combines contact oxidation with filtration technology for aerobic biological wastewater treatment. The core technology involves using porous filter media as a biological carrier for wastewater treatment. At the top of the BAF pool, a water distribution system is installed, which evenly distributes the wastewater across the surface of the filter media, allowing the droplet-like wastewater to fully come into contact with oxygen. Microorganisms attach to the surface of the filter material through adsorption-desorption-readsorption, eventually forming a stable biofilm layer without further desorption. Because there are both aerobic and anoxic zones within the membrane, it has high activity. Once the wastewater passes through the biofilm, pollutants are successfully removed.

UV disinfection works by exposing microorganisms to ultraviolet light, which damages and alters the DNA structure of the microbes, causing immediate death or preventing them from reproducing, thus achieving the purpose of sterilization.

|

Product Features/Advantages:

1.Compared to conventional activated sludge methods, it has a smaller volume, strong adaptability to water quality, good resistance to shock loads, stable effluent quality, and does not produce sludge bulking. The tank uses a new type of flexible three-dimensional filler with a large specific surface area, which facilitates microbial film attachment and detachment. Under the same organic load conditions, it has a high removal rate of organic matter and can improve the solubility of oxygen in water.

2.The entire treatment system is equipped with a fully automatic electrical control system and a fault alarm system for the equipment, making operation safe and reliable. Usually, no dedicated personnel are needed for management; regular inspections, maintenance, and upkeep of the equipment are sufficient.

3.The equipment can be configured as above ground or buried underground. When buried, the overlying soil can be used for landscaping, reducing factory space occupation and surface structures.

|

|

Standardized and Customized Services

We pursue excellence in smart manufacturing. By integrating ERP, PLM, MES, CAPP and other advanced information systems with lean production concepts, relying on digital transformation and automation upgrades, we actively expand the application of big data analysis and artificial intelligence technology, and are committed to intelligent manufacturing to provide customers with excellent products and services.

We not only provide a series of standardized products that have been rigorously tested and have stable performance to meet a wide range of industry needs. We also provide customized services, and our professional design team provides customers with customized solutions to meet their unique needs. Model customers work closely together to ensure that each piece of equipment accurately meets the customer's process requirements and production processes. WTEYA provides all-round services and creates high-quality mechanical products and system solutions with ingenuity.

|

|

Application Scope:

Domestic sewage treatment equipment is suitable for residential areas, villa districts, rural areas, towns, restaurants, hotels, shopping malls, schools, stations, tourist attractions, etc.

|

Company Profile

|

|

Guangdong WTEYA Environmental Technology Co., Ltd. was established in 2019. It is a professional enterprise specializing in industrial wastewater treatment and is engaged in the research and development and manufacturing of evaporation crystallization, drying, filtration, heat exchange technology equipment, and water treatment equipment within the field of multi-process production. The headquarters are located in Tianan Digital City, Dongguan City, Guangdong Province, with a smart production base covering an area of 30,000 square meters. Currently, there are nearly 500 employees, including 250 engineering technical personnel and technicians. The group's main products include MVR evaporators, single-effect evaporators, multi-effect evaporators, crystallizers, heat exchangers, Roots compressors, and various supporting fluid equipment. The enterprise has obtained ISO9001/2015 system certification, CE certification, ISO14001:2004 environmental management system certification, and owns nearly 100 honorary qualifications, including invention patents and utility model patent technologies. The company's product quality, advanced technology, and comprehensive after-sales service have been recognized by customers. The various series of water treatment equipment are sold globally, with support for customization and export to Germany, the United Kingdom, Italy, Denmark, Switzerland, the United States, Canada, Australia, Mexico, Brazil, Argentina, Chile, Colombia, Russia, Ukraine, Romania, India, Indonesia, Vietnam, Thailand, South Africa, Egypt, Cameroon, and many other countries and regions.

|

|

One-Stop Support Services

WTEYA has been specializing in water treatment research and development, manufacturing for over a decade. We integrate R&D, design, production, system integration, project construction, and operation maintenance within our company. With nearly 30,000 square meters of smart manufacturing production bases, as well as production lines for environmental protection-related auxiliary materials, we provide customers with a comprehensive one-stop water treatment equipment system supply chain, offering cost-effective pricing and more comprehensive service guarantees.

|

Intelligent and Efficient Production System

WTEYA possesses sophisticated engineering and manufacturing capabilities. We have constructed a nearly 30,000 square meter manufacturing base in JingShan, Hubei, equipped with multiple sets of precision machining equipment such as a 9-axis gantry automatic welding robot system, jib-type automatic welding robot system, CNC machining centers, fully automatic laser cutting equipment, and fully automatic rolling equipment. With an annual design production capacity of over 500 units, we offer high machining precision, high production efficiency, convenient transportation, and help save time costs for customers.

|

|

Advanced and Reliable Technology

WTEYA has a professional technical R&D team that utilizes advanced treatment process technologies. By integrating MVR evaporation concentration equipment, ECC high-efficiency composite catalysis, ABFT aeration biofluidized bed, and DT/RO/STRO membrane treatment systems, we achieve zero wastewater discharge and resource utilization, helping enterprises to attain both economic benefits.

|

Customized Exclusive Solutions

WTEYA's professional engineering designers provide one-on-one services to tailor-make water treatment solutions for customers. We effectively control the construction and operational costs of projects, helping customers solve various water treatment challenges. At the same time, we offer professional technical support and training guidance, ensuring that customers have peace of mind with our services.

|

Certifications

Exhibition

Packing & Delivery

FAQ

|

Q1: Are you a trading company or a manufacturer?

|

|

A1: We are a professional manufacturer. Our factory is located in Hubei Province, China, covering an area of 30,000 square meters.

|

|

Q2: Do you offer OEM services? Do you supply parts?

|

|

A2: Yes, we can, as long as you provide us with your drawings and detailed requirements.

|

|

Q3: I have wastewater treatment issues, can you help me?

|

|

A3: We offer a complete one-stop solution for industrial water treatment,from design and installation to after-sales service.

|

|

Q4: How can we visit your company?

|

|

A4: You can visit our company on the spot,we can pick you up at the Guangzhou/Shenzhen airport. We can also show you our factory through an online video tour.

|

|

Q5: What's the quality of your machines like?

|

|

A5: Our company has been dedicated to producing water treatment equipment since 2009, with 15 years of experience globally and over 100 successful projects. In addition, we hold the ISO9001 certificate and Alibaba on-site inspection certificate. You may also choose a third-party inspection agency to visit.

|

|

Q6: How is the installation completed?

|

|

A6: We can guide you through a tour via video or photos first. If the customer requires on-site installation, our engineers can be dispatched to your country. However, the customer should pay for the airfare and accommodation during the trip.

|

Share