Industrial Wastewater Mechanical Vapor Recompression Evaporators

Industrial Wastewater Mechanical Vapor Recompression Evaporators

- Introduction to MVR Evaporators

MVR (Mechanical Vapor Recompression) evaporators are a type of mechanical steam recompression evaporator that recycles secondary steam by compressing it to increase its temperature and pressure, allowing it to be used again as a heat source in the heating chamber, thereby achieving energy conservation.2

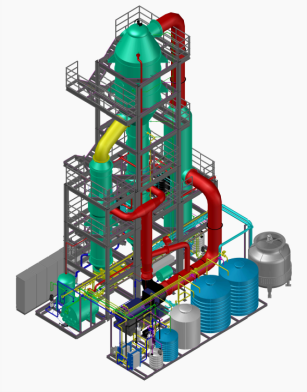

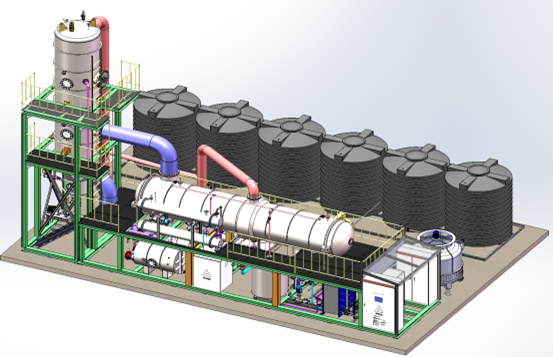

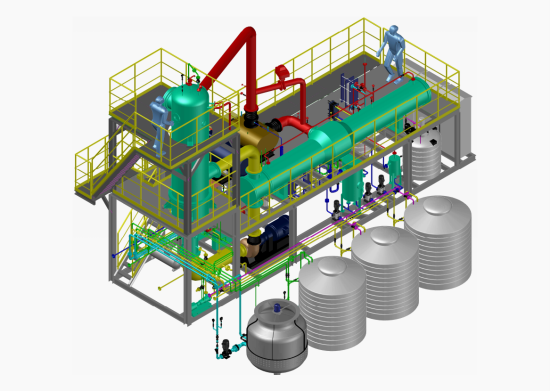

Components of MVR Evaporators

MVR evaporators mainly consist of the following parts:

- Heating Chamber: Used to heat the raw liquid, causing it to evaporate and produce secondary steam.

- Separation Chamber: Used to separate the secondary steam from the concentrated liquid.

- Compressor: Used to compress the secondary steam to increase its temperature and pressure.

- Condenser: Used to condense the compressed secondary steam to recover heat.

- Vacuum System: Used to maintain the vacuum state of the entire system, reducing the evaporation temperature and improving evaporation efficiency.

|

MVR (Mechanical Vapor Recompression) System Specification Table |

|||||

|

Evaporation Capacity(t/h) |

Evaporator Type |

Total Power(KW/h) |

Steam Consumption(t/h) |

Circulating Water Consumption(t/h) |

Footprint (Length* Width* Height/m) |

|

0.5 |

MVR,Forced Circulation |

70 |

0-0.03 |

10 |

6*3*5 |

|

1 |

MVR,Forced Circulation |

110 |

0-0.05 |

10 |

9*8*6 |

|

1.5 |

MVR,Forced Circulation |

180 |

0-0.05 |

20 |

12*7.5*9 |

|

2 |

MVR,Forced Circulation |

213.5 |

0-0.1 |

30 |

12*8*10 |

|

3 |

MVR,Forced Circulation |

275 |

0-0.1 |

50 |

15*8*15 |

|

5 |

MVR,Forced Circulation |

425 |

0-0.2 |

50 |

15*10*15 |

|

7.5 |

MVR,Forced Circulation |

580 |

0-0.3 |

70 |

15*12*15 |

|

10 |

MVR,Forced Circulation |

815 |

0-0.3 |

100 |

12*6*18 |

For other customized MVR system, please contact us now!

Share