1

/

of

4

Ultra Filtration Water purify system , Ultrafiltration UF System

Ultra Filtration Water purify system , Ultrafiltration UF System

Product descriptions from the supplier

Overview

Product Description

Ultrafiltration (UF) System

Ultrafiltration (UF) System is a pressure-driven membrane separation technique situated between microfiltration and nanofiltration, primarily used for the separation, purification, and concentration of macromolecules, colloids, particulates, and pathogens in solutions. The pore size of UF membranes generally ranges from 0.01 to 0.1 micrometers, allowing water, solvents, and small molecular substances to pass through while effectively retaining most microorganisms, proteins, polysaccharides, colloids, and particulate matter.

|

|

Components of the Product:

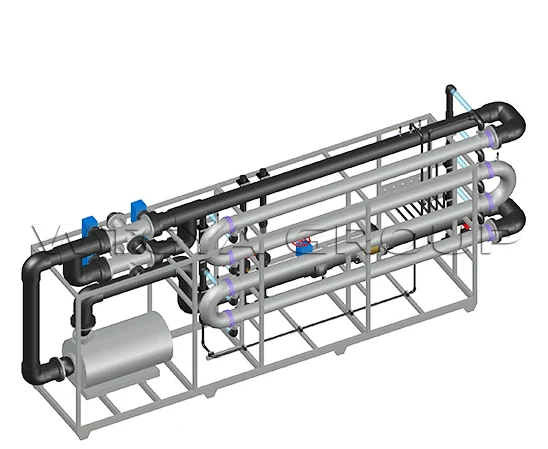

The main components of the ultrafiltration system include: pumps, bag filters, hollow fiber UF membranes, local instruments, dosing systems, fully automatic control systems, and a framework platform.

|

Details Images

Product Parameters

|

|

|

|

|

Technical Principle:

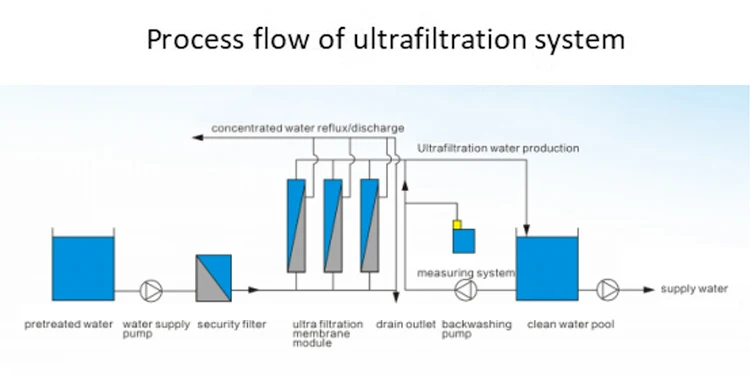

The working principle of Ultrafiltration (UF) is based mainly on membrane separation technology. It is a physical separation process that uses a semipermeable membrane with specific pore sizes as the filtering medium. Under external pressure, as the mixture flows through the UF membrane, water molecules, solvent molecules, and some small molecular substances smaller than the membrane pores can smoothly pass through, while larger molecules, colloidal particles, microorganisms, and pathogens larger than the pore size are retained on the upstream side of the membrane, thus achieving purification, separation, or concentration of the solution. The specific process is as follows:

Feed delivery: The liquid to be treated (such as water, solutions, or slurries) enters the UF system at a certain pressure.

Separation process: When the feed contacts the UF membrane, only components smaller than the membrane's pore size are allowed to pass through. For instance, if the pore size is 0.01-0.1 micrometers, then small molecular substances like water molecules and ions can pass through, while bacteria, viruses, large organic molecules, and colloidal particles are blocked.

Permeate and retention: Small molecular substances that pass through the membrane form the permeate, which is typically quite pure; whereas, larger molecules retained by the membrane accumulate on the upstream side, forming a concentrated solution or what is known as the UF retentate.

Cleaning and regeneration: Over time, the UF membrane surface may have material deposition, adsorption, or even scaling, leading to a decrease in membrane flux. Therefore, regular chemical cleaning or physical backwashing is required to restore the membrane's separation performance.

|

Product Features/Advantages:

The characteristics and advantages of hollow fiber UF membranes mainly include the following aspects:High filtration precision: The pores of hollow fiber UF membranes are extremely small, usually less than 0.1 micrometers, effectively removing microorganisms, colloids, diatoms, and other fine impurities from water, ensuring the quality of the output water.Good hydrophilicity: After special processing, hollow fiber UF membranes have excellent hydrophilicity, enabling high water production rates even under low-pressure environments, and also possess anti-fouling and anti-scaling properties.High mechanical strength: The mechanical strength of hollow fiber UF membranes is better than that of general UF membranes, with a higher resistance to broken filaments, ensuring stable operation and a longer service life of the UF membrane.Strong resistance to chemicals and oxidation: Hollow fiber UF membrane materials have good resistance to chemicals and oxidation, allowing for stable operation in various harsh environments without being easily oxidized or corroded.Good cleanability: If a hollow fiber UF membrane becomes clogged, it can be cleaned using various methods to restore its original performance and extend its service life.Strong adaptability: Hollow fiber UF membranes are suitable for various water quality conditions, especially in the field of industrial wastewater, such as textile wastewater, chemical wastewater, coking wastewater, etc.In summary, hollow fiber UF membranes have the advantages of high filtration precision, good hydrophilicity, high mechanical strength, strong resistance to chemicals and oxidation, good cleanability, and strong adaptability. Therefore, they are widely used in water treatment, beverage processing, wastewater treatment, and other fields.

|

|

Standardized And Customized Services

We pursue excellence in smart manufacturing. By integrating ERP, PLM, MES, CAPP and other advanced information systems with lean production concepts, relying on digital transformation and automation upgrades, we actively expand the application of big data analysis and artificial intelligence technology, and are committed to intelligent manufacturing to provide customers with excellent products and Serve. We not only provide a series of standardized products that have been rigorously tested and have stable performance to meet a wide range of industry needs. We also provide customized services, and our professional design team provides customers with customized solutions to meet their unique needs. Model customers work closely together to ensure that each piece of equipment accurately meets the customer's process requirements and production processes. Witya provides all-round services and creates high-quality mechanical products and system solutions with ingenuity.

|

|

Application Scope:

The scope of application for hollow fiber ultrafiltration (UF) membranes is extremely broad, mainly applied in the following fields:Municipal, power, steel, petrochemical, textile, food, and other sectors: In these areas, hollow fiber UF membranes can be used for the advanced treatment and reuse of wastewater, as well as for the treatment of process water to meet various water quality requirements.Drinking water treatment: Hollow fiber UF membranes can be used for the purification of municipal water supplies, removing suspended solids, colloids, bacteria, viruses, and other impurities to provide safe and reliable drinking water.Seawater desalination: Hollow fiber UF membranes can be used for seawater desalination and as a pretreatment for reverse osmosis systems, enhancing the efficiency and quality of seawater desalination.Food and biotechnology sectors: Hollow fiber UF membranes are used for purification, concentration, and separation in the food and biotechnology industries, such as clarification of juices, concentration of dairy products, and concentration of alcohol, ensuring product quality and purity.Industrial wastewater treatment: Hollow fiber UF membranes can be used for the treatment of industrial wastewater, removing harmful substances and heavy metal pollutants, achieving wastewater recovery and reuse.Additionally, hollow fiber UF membranes can also be applied in chemical processes, biomedical, environmental protection, and energy recovery fields. Overall, with their high filtration precision, excellent separation performance, and wide range of applicability, hollow fiber UF membranes are playing an increasingly important role in water treatment, environmental protection, food processing, and other areas.

|

Company Profile

|

|

Guangdong WTEYA Environmental Technology Co., Ltd. was established in 2019. It is a professional enterprise specializing in industrial wastewater treatment and is engaged in the research and development and manufacturing of evaporation crystallization, drying, filtration, heat exchange technology equipment, and water treatment equipment within the field of multi-process production.

The headquarters are located in Tianan Digital City, Dongguan City, Guangdong Province, with a smart production base covering an area of 30,000 square meters. Currently, there are nearly 500 employees, including 250 engineering technical personnel and technicians.

The group's main products include MVR evaporators, single-effect evaporators, multi-effect evaporators, crystallizers, heat exchangers, Roots compressors, and various supporting fluid equipment. The enterprise has obtained ISO9001/2015 system certification, CE certification, ISO14001:2004 environmental management system certification, and owns nearly 100 honorary qualifications, including invention patents and utility model patent technologies.

The company's product quality, advanced technology, and comprehensive after-sales service have been recognized by customers. The various series of water treatment equipment are sold globally, with support for customization and export to Germany, the United Kingdom, Italy, Denmark, Switzerland, the United States, Canada, Australia, Mexico, Brazil, Argentina, Chile, Colombia, Russia, Ukraine, Romania, India, Indonesia, Vietnam, Thailand, South Africa, Egypt, Cameroon, and many other countries and regions.

|

|

One-Stop Support Services

WTEYA has been specializing in water treatment research and development, manufacturing for over a decade. We integrate R&D, design, production, system integration, project construction, and operation maintenance within our company. With nearly 30,000 square meters of smart manufacturing production bases, as well as production lines for environmental protection-related auxiliary materials, we provide customers with a comprehensive one-stop water treatment equipment system supply chain, offering cost-effective pricing and more comprehensive service guarantees.

|

Intelligent and Efficient Production System

WTEYA possesses sophisticated engineering and manufacturing capabilities. We have constructed a nearly 30,000 square meter manufacturing base in JingShan, Hubei, equipped with multiple sets of precision machining equipment such as a 9-axis gantry automatic welding robot system, jib-type automatic welding robot system, CNC machining centers, fully automatic laser cutting equipment, and fully automatic rolling equipment. With an annual design production capacity of over 500 units, we offer high machining precision, high production efficiency, convenient transportation, and help save time costs for customers.

|

|

Advanced and Reliable Technology

WTEYA has a professional technical R&D team that utilizes advanced treatment process technologies. By integrating MVR evaporation concentration equipment, ECC high-efficiency composite catalysis, ABFT aeration biofluidized bed, and DT/RO/STRO membrane treatment systems, we achieve zero wastewater discharge and resource utilization, helping enterprises to attain both economic benefits.

|

Customized Exclusive Solutions

WTEYA's professional engineering designers provide one-on-one services to tailor-make water treatment solutions for customers. We effectively control the construction and operational costs of projects, helping customers solve various water treatment challenges. At the same time, we offer professional technical support and training guidance, ensuring that customers have peace of mind with our services.

|

Certifications

Exhibition

Packing & Delivery

FAQ

|

Q1: Are you a trading company or a manufacturer?

|

|

A1: We are a professional manufacturer. Our factory is located in Hubei Province, China, covering an area of 30,000 square meters.

|

|

Q2: Do you offer OEM services? Do you supply parts?

|

|

A2: Yes, we can, as long as you provide us with your drawings and detailed requirements.

|

|

Q3: I have wastewater treatment issues, can you help me?

|

|

A3: We offer a complete one-stop solution for industrial water treatment,from design and installation to after-sales service.

|

|

Q4: How can we visit your company?

|

|

A4: You can visit our company on the spot,we can pick you up at the Guangzhou/Shenzhen airport. We can also show you our factory through an online video tour.

|

|

Q5: What's the quality of your machines like?

|

|

A5: Our company has been dedicated to producing water treatment equipment since 2009, with 15 years of experience globally and over 100 successful projects. In addition, we hold the ISO9001 certificate and Alibaba on-site inspection certificate. You may also choose a third-party inspection agency to visit.

|

|

Q6: How is the installation completed?

|

|

A6: We can guide you through a tour via video or photos first. If the customer requires on-site installation, our engineers can be dispatched to your country. However, the customer should pay for the airfare and accommodation during the trip.

|

|

Q7: What if we encounter machine problems?

|

|

A7: Show us pictures or videos of the problem. If your staff can resolve it, we will send the solution to you via video or images. If the problem is beyond your control, our engineer will be sent to your factory (the customer will cover the travel expenses).

|

|

Q8: What about the warranty and spare parts?

|

|

A9:We provide a 1-year warranty for the machines, and most parts can be found in the local market, or you can also purchase parts from us.

|

Share